Teeth on the gear set are excessively worn chipped or broken.

Ring and pinion wear pattern chart.

The images below illustrate both acceptable and unacceptable ring and pinion gear patterns.

When the pinion is too far in towards the ring gear the pattern is low toward the base of the gear teeth.

Ring gear tooth profile face hobbing face milling the toe of the gear is the portion of the tooth surface at the end towards the center.

This pattern indicates excessive pinion depth.

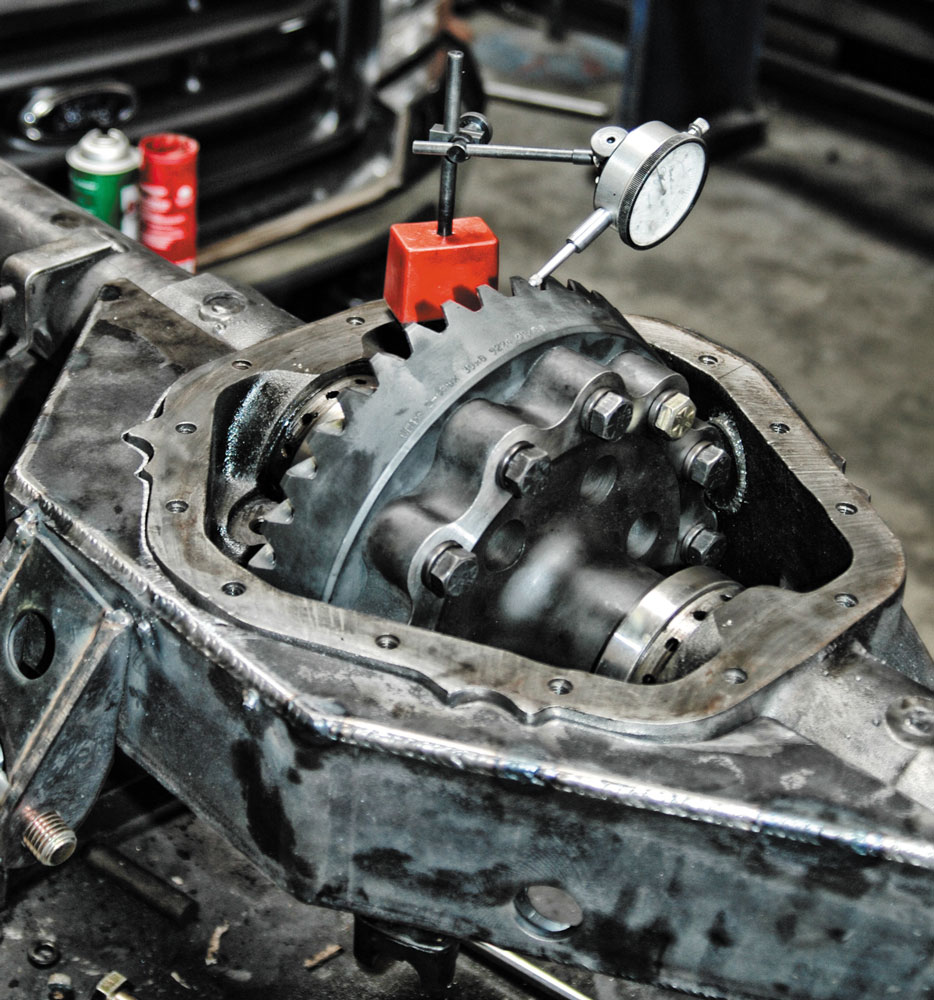

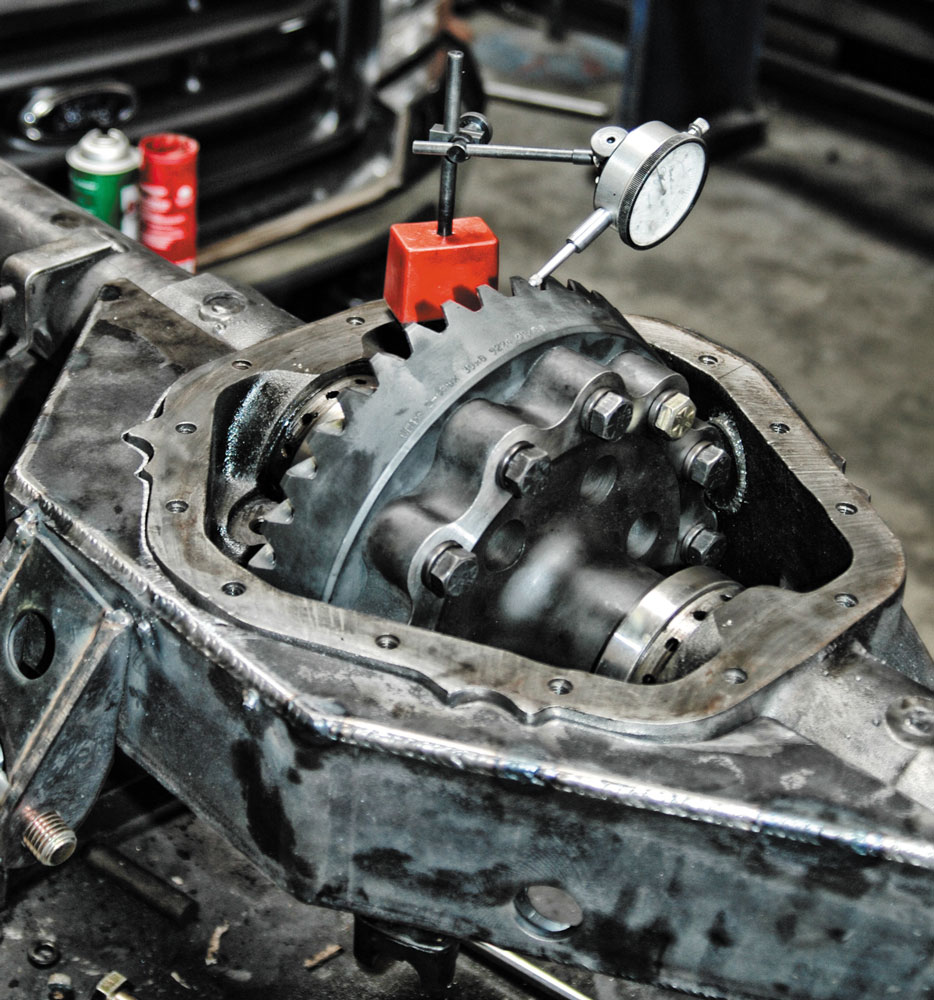

Begin by setting proper pinion bearing preload total turning preload and ring gear backlash.

Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up.

Use gear marking compound to paint all of the ring gear teeth.

The heel of the gear tooth is the portion of.

After the gears are installed using a pinion depth setting tool you should always check the wear pattern using a marking compound.

Proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation.

Ring gear and pinion tooth pattern interpretation the final pinion position will be verified by using the gear contact pattern method described as follows.

Load the ring gear and run a full contact pattern check.

For more in depth information about ring and pinion gear patterns and how.

The ring gear is too far in toward the pinion.

You should see the wear pattern closer to the toe of the tooth with most gear sets.

Ring and pinion gear pattern interpretation adjustment.